PRODUCT

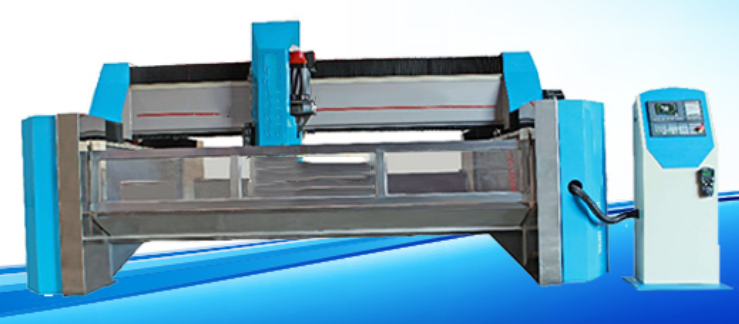

1. What is Glass Engraving Machine?

Glass engraving machine is a machine which can engrave, curve different patterns or figures(mainly lines or stripes)on flat glass. The Working Table covered with rubber, have vacuum system which makes it possible to quickly locate the glass without the aid of any mechanical device. After placing the glass on the working table, the machine will automatically conduct engraving, writing including rough engraving, fine carving, polishing and tool changing according to the working program.

2. Operating Principle

Firstly, design the patterns or figures with CAD software, then transfer the CAD drawing to Baineng System and set parameters. The Baineng System can calculate the best route and generate code. Thirdly copy the codes to the computer. The computer will read the codes and transfer to the machine, so the machine can start to work automatically.

3. Function

The machine can be used for engraving or curving different patterns or figures on flat glass,including below shaped engraving

V Engraving U Engraving VUV Engraving Wave Engraving

Seagull Concave Engraving Out of Center V Engraving 3P Engraving

Bubbles Arc Engraving 4V Engraving Deep V Engraving

4. Application

Our machine is mainly use for:Art Glass, Furniture Glass, Home Appliances glass, Medical Apparatus Glass,etc.

1) Art Glass:Apply to Decorate KTV、PUB、TV Background Wall ,Club and so on.

2) Furniture Glass:Most to Engrave on Mirror,and also for Furniture Glass Series.

3) Sliding Door:It’s very popular to engrave linear patterns on the Glass Door .

4) Home Appliances glass:Such as Gas Stove Panel,Kitchen Ventilator,refrigerator,etc.

Some commonly tools:

5. Advantages.

a. Software Advantage: Most software used now usually needs to generate different kinds of Codes because patterns will use different tools, contains different lines or stripes. However Baineng Software can only generate one code once parameters are set, no matter how complicated the patterns are or how many tools are used, thus not only save a lot of time, but also easy to operate.

b. High processing speed and low processing cost. Our machine can engrave the glass 6-7 meters per minuter.

c. The hiding tool library:unlike other manufacturer make the tools explosive to the air,we develop the hiding tool library to protect the tools from rusting.And it’s fully automatical tools change.

d. To load and unload the glass more easily and protect people from the glass powder while the machine is working, we design the automatic contraction door.

e. To prevent freezing and blocking, we design Vacuum aluminum.

f. We use wireless remote control to adjust the center.

6. Configuration Details

1)CNC system and Wireless handle remote from TAIWAN SYNTEC

2)Servo System;AC servo system from TAIWAN SYNTEC .

3) Bearing, Ball Screw, Linear Guide: from Japan THK or TAIWAN TBI.

4) Electrical Equipment: from Germany Schneider

5) Two air cylinder to change the tool.

7. Technical Parameter and Price

|

机型 MODEL NO. |

BN-2412D |

BN-3016E |

BN-2620E |

BN-3020E |

BN-3720E |

BN-2060F |

|

|

X,Y,Z轴行程 Stroke of X.Y.Z-axis |

2400*1200*135(mm) |

3000*1600*135(mm) |

2600*2000*135 (mm) |

3000*2000*135(mm) |

3700*2000*135(mm) |

2000*6000*135 (mm) |

|

|

最大玻璃加工尺寸 Max size of glass |

2400*1200(mm) |

3000*1600(mm) |

2600*2000(mm) |

3000*2000(mm) |

3700*2000(mm) |

2000*6000(mm) |

|

|

最小玻璃加工尺寸 Min size of glass |

200*200 (mm) |

200*200 (mm) |

200*200 (mm) |

200*200 (mm) |

200*200 (mm) |

200*200 (mm) |

|

|

玻璃厚度范围 Glass Thickness |

2-40(mm) |

2-40(mm) |

2-40(mm) |

2-40 (mm) |

2-40(mm) |

2-40 (mm) |

|

|

C轴转速 Rotating Speed of C-Axis |

15m/min |

15m/min |

15m/min |

15m/min |

<span style="font-family: 宋体; font-size: 7. |

||