PRODUCT

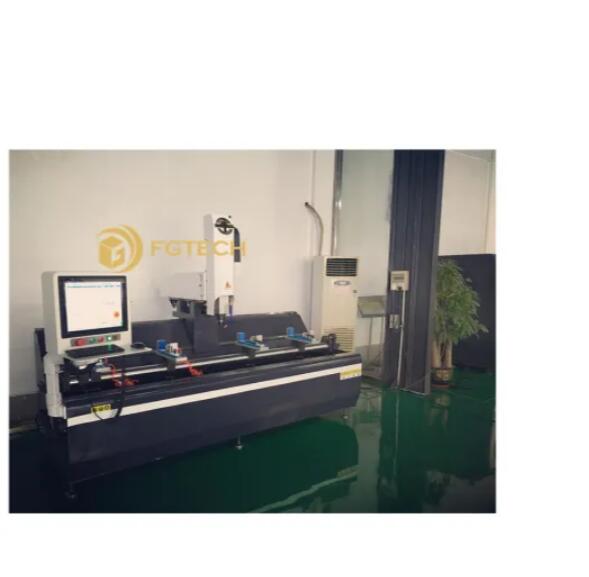

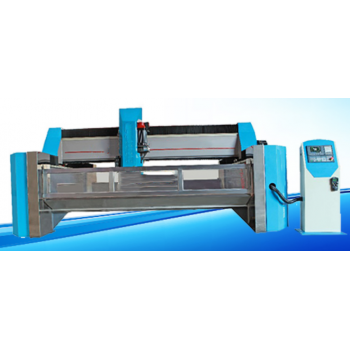

Fgc-660 3 Axis Machining Center for Aluminum Profile

KT-660 Professional Profile Machining Center is special designed for aluminum profile industry. With Windows NT professional operating system and Germany PA computerized four-axis industrial digital control system, the machine can be used to milling different of aluminum profile.

Basic Info.

1. Main introduction of the machine

KT-660 Professional Profile Machining Center is special designed for aluminum profile industry. With Windows NT professional operating system and Germany PA computerized four-axis industrial digital control system, the machine can be used to milling different of aluminum profile.

Main components of the machine

2.1 Main spindle: Original (ATC) HSD main spindle (7.5KW) from Italy

2.2 all-steel machine frame: relief treatment of stress, precision machine processing

2.3 Linear guide way: HIWIN(Taiwan China)linear guide way are installed the machine(X,Y,Z axis)

2.4 Transmission on X,Y axis:YCC (Taiwan) rack gear

2.5 Transmission on Z axis: HIWIN(Taiwan China)ball screw

2.6 Tool magazine: 6-position automatic tool magazine; offers 6 set of ISO30/ER25 Italy imported tool holder: 2 set of Ø6, Ø8 milling bits separately; 2 set of Ø5-Ø6, Ø7-Ø8 spring collects separately.

2.7 Mill cutter checking system: Adopt automatic mill cutter checking system to checking the right location of the mill cutter.

2.8 Worktable: 6 sets of adjustable pneumatic clamping tables

PS. New Clamping:

2.9 Driven system (servo motor): YASKAWA (Japan) high performance spindle drive servo motor.

2.10 Towline: High performance twine from Germany

2.11 One set of oil cooling system

2.12 2 set of pneumatic positioning system

2.13 Professional industrial controlling system

2.14 One piece of 3D portable controller

2.15 Control box: main electrical component, engineering-control machine,control system are all imported from other countries

2.16 Operation system: Germany PA control system in English

2.17 Pneumatic components: AIRTAC BRAND

2.18 Electrical components: SCHNEIDER

2. Technique details

| item | unit | KT-660R | |

| Cutting dimension | X | mm | 6500 |

| Y | mm | 600 | |

| Z | mm | 300 | |

| Processing precision |

Position. | mm | ±0.1 |

| Preposition | mm | ±0.05 | |

| Extent of perpendicularity | mm/mm | 0.1/100 | |

| Extent of circularity | mm | 0.1 | |

| Rough | um |

Ra 12.5 um |

|

| Feed speed | X Axis | m/min | 52 |

| Y Axis | m/min | 35 | |

| Z Axis | m/min | 18 | |

| Tool change | s | 20 | |

| Main axis | power/rev | kw/rpm | 7.5/24000 |

| Servo motor (Yaskawa) |

X | Kw | 0.85+0.85 |

| Y | Kw | 0.85 | |

| Z | Kw | 0.85 | |

| R(tool) | Kw | 0.4 | |

| Tool clamping | Diameter max. | mm | Ø 16 |

| Pressure/total power | 380V 50HZ/10KW | ||

| Dimension of the machine | mm | 7550*1300*1600mm | |

| Dimension of controlling box | mm | 600×1400×1800 | |

| Integrity power | Power | KVA | 20 |

| Air pressure | Kg/cm2 | 6~8 | |