INDUSTRY NEWS

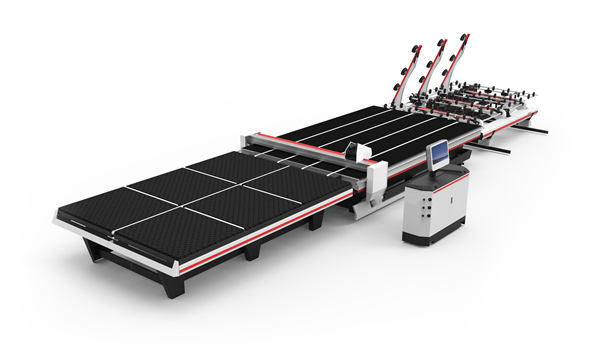

How the glass cutting machine works

The pace of social development is constantly advancing, and technology is also constantly improving. As a necessary mechanical glass cutting machine for glass processing, it is slowly integrating into the corners of the market.

The editor of this article will mainly talk about the related matters of the glass cutting machine, and I hope it will be helpful to everyone.

What is glass cutting

First explain a misunderstanding, cutting glass does not mean actually cutting the glass with a knife.

Glass cutting reality refers to the operation of scribing on the glass or making marks or grooves on the glass.

This operation weakens the glass along the score, and then cracks along the seam of the score with the help of external force.

Whether it is home improvement, construction or other types of glass cutting technology, they are all the same, the only difference is the size and thickness of the glass.

Important components of glass cutting machine

The core main components of the glass cutting machine are the valve stem (handle) and the roller.

The roller is not as sharp as the blade as we thought, but it has an angled construction.

The scroll wheel can move freely, but when he touches the glass and causes pressure, he pushes the handle to roll.

How to use a glass cutter to cut glass

When using a glass cutter to cut glass, if the operator uses the correct method, you can see the cutting line roller.

It should be noted here that the glass cutting machine must cut the line and the glass vertically.

The next step is to control the pressure.The operator's proficiency is high enough to easily control the pressure and know what size and thickness of glass is suitable for what pressure.

When the pressure is low, it is impossible to cut, and when the pressure is high, it is easy to damage. This is the operator's own control.

Glass cutting machine operation details

A piece of glass must be cut with the same pressure from the beginning of the decision to the end, otherwise it is easy to break the glass or discard it directly.

All processes must be kept on the cutting table and never put the glass on the edge of the cutting table.

After learning about the glass cutting machine, if you are interested in buying a machine, the editor hopes that everyone can visit it on the spot. After all, shop around and choose a well-known company is more reliable. Gebo Industry has focused on the glass processing machinery industry for many years, we can definitely help you, please contact us.