INDUSTRY NEWS

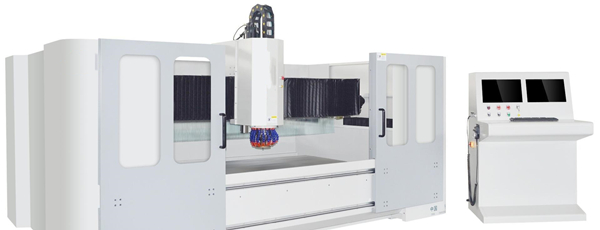

Advantages of CNC Glass Processing Center-Functional Advantages of Glass Processing Center

The emergence of CNC glass processing centers has made my country's glass manufacturers take a big step forward, greatly improving the production of molded glass in the glass industry and shortening the installation time.

All these benefits are the credit of the CNC glass processing center, which effectively alleviates the problem of manual handling of large amounts of heavy glass. The CNC glass processing center has a wide range of glass operations and can be used in a variety of production platforms.

Advantages of glass processing center

High precision:

Laser sensor ensures precise positioning

Regular automatic re-sharpening and guarantee of tool quality

Get the perfect drilling effect by simultaneously drilling from above and below

Automatically remove glass waste

flexibility:

An interface is provided to allow direct calling of the relevant data of the CNC program

Allows separate grinding and milling tools to approach the entire working width of the glass sheet

Process reliability:

The most automated production of original glass: drilling, grinding and milling operations on one machine, saving time and improving quality

Less troublesome processing and setting operations

Simple maintenance components are enough, reducing maintenance time

Accurately detect glass by touching the glass with a measuring probe

Simple operation:

Online operation, save labor time cost and increase product manufacturing efficiency

Automatic detection ensures that the glass is in the grinding and grinding stage during the production process

Gebo Industry is a very innovative company. We are very aware of the needs of users and actively develop more functions suitable for customers. If you have any glass machinery needs, we will serve you wholeheartedly.